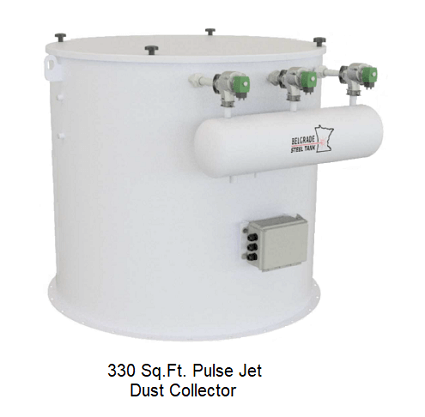

| DUST COLLECTOR SPECIFICATIONS | |

| Total Filtration Area | 330 Ft.² |

| Air To Cloth Ratio ( ACFM / Ft.² ) | 4.8 |

| Pressure Drop | 6” |

| Air Capacity | 1600 |

| Outlet Area ( Ft.² ) | 0.83 |

| Cleaning Method | Pulse Jet |

| Inlet Dust Concentration at 15 Gm./ Ft.³ | 25,000 |

| Outlet Emissions ( Gm./ Min. ) | 2.50 |

| Outlet Dust Loading ( Gm./ Ft.³ ) | .0015 |

| Air Consumption | 8 CFM |

| Solenoids | 120/60 ASCO Power Pulse Valve (Qty:3) |

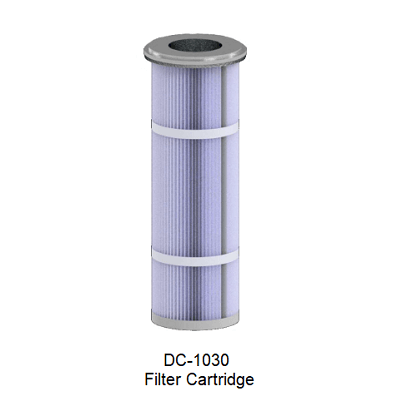

| FILTER CARTRIDGE SPECIFICATIONS | |

| Dimensions | 11.09” O.D. x 5.75” I.D. x 30” Tall |

| Top End Cap | G60 Galvanized-Open with 11″ Flange |

| Bottom End Cap | G60 Galvanized-Closed |

| Gasket | 5/8” Height x 10” I.D., Neoprene |

| Outline Retainer | Retainer Bands |

| Inner Core | Galvanized Expanded Metal 72% Open |

| Filter Area | 55 Ft.² |

| Fiber | 100% Spun Bond Polyester |

| Material Weight | 8 oz. / Yd.² |

| Permeability | 24 CFM |

| Mullen Burst Dry | 388 PSI |

| Temperature Limit | 275 Degrees Fahrenheit |

| Efficiency | 99.99% |

OPERATION RECOMMENDATIONS: Supply unit with 100 PSI air pressure and 110 volt or 12 volt power. Turn on unit when filling cycle begins and operate continuously for 20 minutes after filling cycle completes.