Benefits of An Aggregate Batcher

- Consistency: An aggregate batcher ensures that each batch of concrete is consistent in terms of the type and quantity of aggregates used, which is crucial for producing reliable and uniform concrete mixes.

- Efficiency: By automating the weighing and proportioning process, an aggregate batcher streamlines the concrete production process, increasing efficiency and reducing labor requirements.

- Quality: Accurate proportioning and weighing contribute to the quality of the concrete mix, leading to better performance and durability of the final product.

- Cost-Effectiveness: Reduced waste and improved efficiency result in cost savings in concrete production.

Summary

An aggregate batcher is an essential component in a concrete plant responsible for accurately weighing and proportioning aggregates to create consistent, high-quality concrete mixes. Its precise operation and automation capabilities contribute to the efficiency and cost-effectiveness of concrete production while ensuring the quality of the final product.

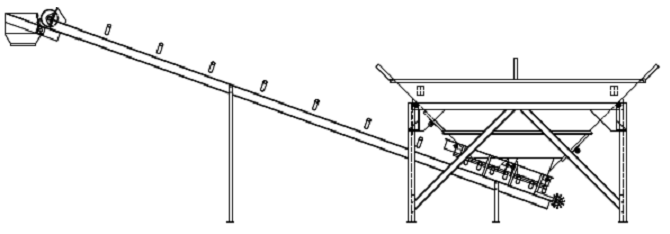

Accumulative Aggregate Batcher

12 Yd.³ Capacity Scale Hopper consisting of 1/4” and 3/16” Material • 12” x 38” Gate with 3 1/2” x 8” Air Cylinder • Air Vibrator • (4) 15,000# Load Cells with Digital Indicator • Scale Support Stand • Sand Blast, Prime, and Paint

Options: 10 Yd.³ Capacity

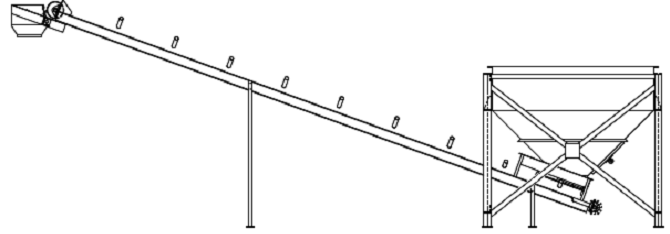

Truck Charging Conveyor

30” Wide 3/16 x 1/16 2-Ply Belt (300 FPM / 576 TPH) • 8” Channel Frame with 20° and 35° Trough Idlers and Returns • 14” Head Pulley with Herring-bone Lagging on 2 – 3/16” Drive Shaft and Pillow Block Bearings • Individual Belt Tighteners with 3/4” Sealed-In-Grease Threaded Rods • 10 HP 3-Phase Motor T.E.F.C. • Shaft Mount Gear Box Complete with Double Groove Pulleys, Belts, and Backstop • Discharge Hopper with Rubberized Sock • Torsion Style Belt Wiper • Water Pipe • Intermediate Support Stand • Sand Blast, Prime, and Paint

Deccumulative Aggregate Batcher

Two Compartment 12 Yd.³ Capacity Scale Hopper • Weigh System with Digital Indicator and Decumulative Batching Software • Structural Support Stand • (2) Discharge Gates with Air Cylinders and Limit Switches • (2) Air Vibrators • Collecting Hopper with Gum Rubber Boot • Sand Blast, Prime, and Paint